How We Transform MRI And CT Scans Into 3D Models

Aside from being able to look at and model bones, ScanIP also allows our team to perform reconstruction that is designed to fit an individual’s needs.Aside from being able to look at and model bones, ScanIP also allows our team to perform reconstruction that is designed to fit an individual’s needs.

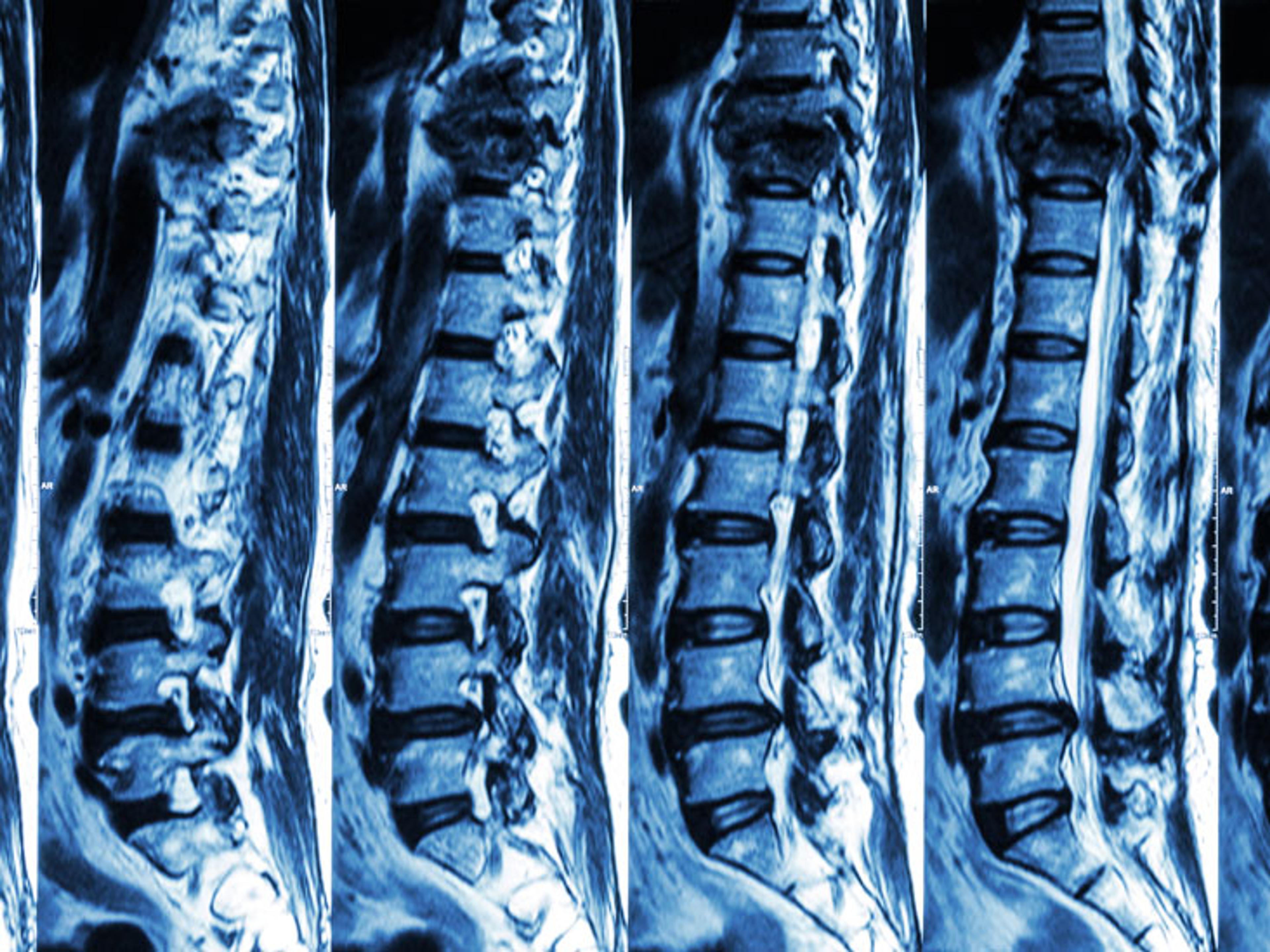

Being able to create accurate medical devices that are closely matched to a patient’s unique anatomy requires precision imaging, measurements, and design. A critical part of PrinterPrezz’s unique medifacturing™ workflow is our process of turning magnetic resonance imaging (MRI) and computed tomography (CT) scans into a 3D CAD image that can be manipulated and used for 3D printing.

PrinterPrezz employs a team of experienced orthopedic surgeons that work with innovation hospitals. MRI and CT scans can be given to us more securely and quickly, ultimately speeding up the process of producing an effective implant. In the early stages of our workflow, we utilize Synopsys’s Simpleware ScanIP. Our surgeons and engineers are able take MRI and CT scan data from the hospital and perform analysis and segmentation—effectively taking the solid scan data and slicing the structures up layer by layer. This allows us to “see into” the 3D scans and apply unique modeling techniques. It is the first critical point in the workflow.

Aside from being able to look at and model bones, ScanIP also allows our team to perform reconstruction that is designed to fit an individual’s needs. MRI and CT scans arrive in a stack of sliced 2D images. Constructing a scan into a virtual 3D model that can be manipulated requires specialized software, such as ScanIP, which analyzes the images and produces a 3D model. Tools inside ScanIP allow our designers to isolate bone structures from other body features such as organs and muscle.

After a 3D model is created, our engineers print the model in resin, providing surgeons with a physical representation of the MRI or CT scan. From here, surgeons can work with our team to investigate the optimal procedure for a patient. Specialized tools like Simpleware ScanIP are used again for the second critical stage: verifying that a 3D printed model accurately matches what was designed on the computer.

MRI and CT scans come into play again, scanning the 3D printed part externally and internally. This allows us to slice through the 3D printed model, layer by layer, allowing our engineers to examine the internal structure of the model to identify any potential areas for structural and design improvements. Using specialized tools, such as Synopsys Simpleware ScanIP with PrinterPrezz’s part metrology system, allows designers to verify that what is being made is consistent with what is being designed at an early stage.

This blog is provided for general informational purposes only. The information in each post on this blog (collectively, “Information”) may be changed at any time without notice and is not guaranteed to be complete, correct, or up-to-date and may not reflect the most current developments on the topics covered. The Information is protected by United States and international copyright laws and may not be reproduced, distributed, transmitted, cached or otherwise used except with the prior written permission of PrinterPrezz.

THE INFORMATION IS PROVIDED TO YOU “AS IS.” YOUR ACCESS TO AND USE OF THE BLOG IS AT YOUR OWN RISK. TO THE EXTENT PERMITTED BY LAW, PRINTERPREZZ DISCLAIMS ALL CONDITIONS, REPRESENTATIONS AND WARRANTIES, EXPRESS, IMPLIED, STATUTORY OR OTHERWISE, INCLUDING ANY WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. PRINTERPREZZ DISCLAIMS LIABILITY FOR ANY DAMAGES, INCLUDING BUT NOT LIMITED TO LOST PROFITS OR INCOME, LOST BUSINESS, OR LOST DATA, OR FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, EXEMPLARY, PUNITIVE, SPECIAL, OR INCIDENTAL DAMAGES ARISING FROM OR RELATING TO THE BLOG.

Copyright © 2019, PrinterPrezz, Inc., All Rights Reserved.